Pantheon Design alleviates provide chain uncertainty with factory-grade 3D printing • TechCrunch

[ad_1]

Within the midst of the pandemic, Pantheon Design, a maker of commercial 3D printers from Vancouver, BC, instantly discovered itself getting orders from factories within the Midwest, the middle of heavy industries. The rationale? These producers had been having a tough time getting components out of China as COVID-19 restrictions within the nation squeezed world provide chains.

Considered one of Pantheon Design’s e-mobility clients waited 18 months earlier than its injection molds, that are used for producing components, arrived from China. In case your electrical automobile or dwelling equipment order is taking longer to reach, chances are high port closures and lockdowns within the manufacturing unit of the world are messing up your provider’s manufacturing timeline.

For a very long time, 3D printers had been too costly, sluggish, and short-lived to be economically viable for producers, observes Bob Cao, co-founder and CEO of Pantheon Design, as he speaks to TechCrunch as one of many Disrupt Startup Battlefield 200 corporations. Most of the 3D printing startups that safe massive VC checks are run by sensible individuals who have by no means been in an actual manufacturing unit, which is sizzling and smelly, says the entrepreneur. “So their machines break down on a regular basis.”

“They make the product for prototyping, however they attempt to promote the thought for manufacturing,” he provides.

Cao’s founder story follows a well-known sample seen amongst engineers: 5 years in the past, he and his co-founders purchased a bunch of 3D printers to construct merchandise for industrial clients, however the third-party units weren’t assembly their expectations, in order that they got down to construct their very own.

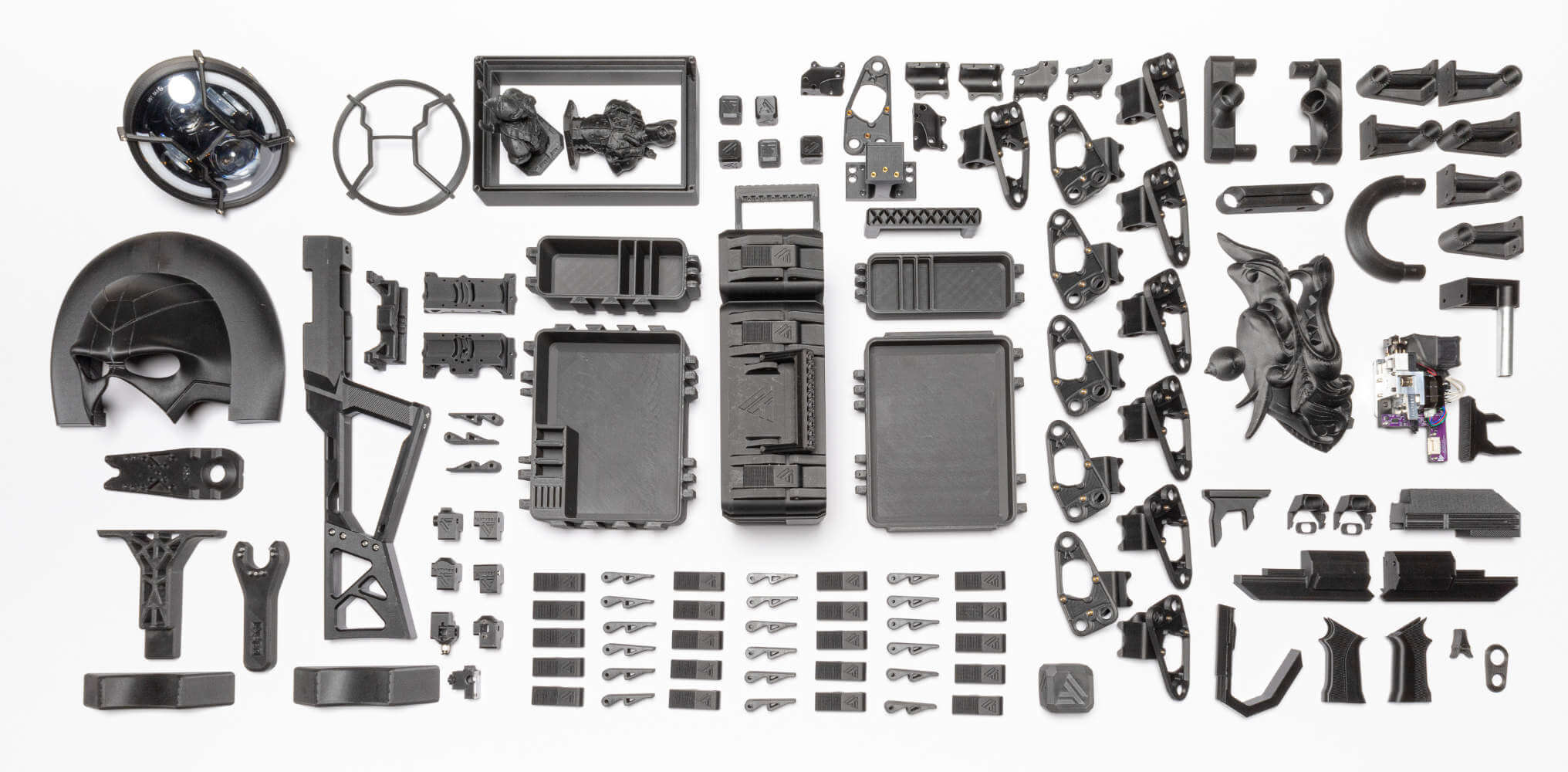

Components created by Pantheon’s 3d printer.

The result’s the HS3 3D printer, which is a sleek-looking dice measuring 300mm on all sides and weighing 46.7 kilograms, that includes black anodized aluminum, which has been handled to attain a sturdy end. The gadget is ready to print carbon fiber components which might be as sturdy as metallic and 5-10 occasions sooner than different choices in the marketplace due to the startup’s patented strategies, based on Cao. Furthermore, it’s capable of do it at a aggressive price even compared to Chinese language suppliers.

The startup has bought 40 HS3 models — all assembled in-house in Vancouver with components manufactured in Canada — since beginning delivery the machine 9 months in the past. Every printer prices $15,000, however the larger chunk of the corporate’s revenues comes from promoting filaments. Additionally referred to as the “ink” for 3D printers, filaments vary from $50-150 a kilo, which brings a pleasant 90% revenue margin, and a lot of the firm’s clients spend about $500-800 a month on them.

Pantheon Design has raised $800,000 in funding from a mixture of buyers in Canada and the U.S., together with the Boston-based accelerator Techstars. The corporate can be buoyed by revenues it generated from its earlier enterprise of printing merchandise and prototypes for shoppers, and two of its proudest moments embrace printing whole idea bikes for Honda and all of the sci-fi props within the Netflix movie The Adam Mission.

Source link